The ROI of Predictive Maintenance: Real-World Case Studies on AI and IoT Impact Across Industries

Unlock the ROI of predictive maintenance—slash downtime, boost safety, and save millions. Discover how AI and IoT are revolutionizing industry and infrastructure, turning data into decisive action and foresight.

From factory floors to city streets, predictive maintenance is quietly becoming the unsung hero of the digital age. But what does the ROI really look like when AI and IoT step into the ring?

Why Predictive Maintenance Isn’t Just Hype: Setting the Scene

If you’ve ever spent a Monday morning wrestling with a coffee machine that failed right before your 8am meeting—imagine that, but with million-dollar turbines, commuter trains, or power grids. Now, sprinkle in AI, IoT sensors, and a dash of data wizardry. Welcome to predictive maintenance: where breakdowns are practically psychic, downtime shrinks, and budgets breathe a sigh of relief.

"In our first year of predictive maintenance, we cut unplanned downtime by 37%. That’s not a rounding error—it’s a revolution."

— Operations Director, Global Manufacturing Firm

The Numbers Game: ROI Metrics That Matter

Let’s get straight to the money (and the metrics):

- Downtime Reduction: Companies report 30–50% less unplanned downtime after deploying IoT-based predictive maintenance (Automation.com, 2025).

- Cost Savings: Maintenance costs drop by 12% on average, while equipment lifespan can extend by up to 40% (PwC, 2025).

- Safety & Sustainability: Early alerts mean fewer accidents and optimized energy use, with some manufacturers reporting 9% higher overall equipment effectiveness (OEE).

But these aren’t just statistics—they’re life (and budget) changers. Let’s hit the shop floor, the control room, and city hall to see how the story unfolds.

Manufacturing: When Machines Talk, Wallets Listen

Case Study: Automotive Plant, Midwest USA

- Before: 42 hours/month average downtime. $1.2M/year lost to reactive maintenance. Safety incidents: 2 per quarter.

- After Predictive Maintenance: 19 hours/month downtime. $700K/year savings. Zero safety incidents in first 9 months.

How? An AI-driven analytics platform monitored vibration, temperature, and oil quality in real time. The system flagged failing bearings days before catastrophic failure, letting teams schedule fixes during planned lulls. The plant’s maintenance chief summed it up: “We don’t fix what isn’t broken—unless the data says it’s about to be.”

Energy & Utilities: Keeping the Lights On (and the Bills Down)

Case Study: Wind Farm Consortium, Northern Europe

- Before: Turbine failures every 6 weeks, emergency repairs costing €85,000 each. 7% annual energy loss due to downtime.

- After Predictive Maintenance: Failures down to once every 6 months. Emergency repair costs slashed by 68%. Energy loss: 1.5%.

IoT sensors and AI models analyzed blade stress and gearbox health, predicting failures weeks in advance. Not only did this save cash, but it also boosted renewable energy output—making the CFO and the planet equally happy.

Transportation: Trains, Planes, and Predictive Pains (or Lack Thereof)

Case Study: National Rail Operator, Asia-Pacific

- Before: 160 train delays/month due to equipment breakdowns. Public complaints: legendary.

- After Predictive Maintenance: Just 27 delays/month. Customer satisfaction up 24%. Maintenance overtime costs reduced by 34%.

Onboard IoT sensors tracked wheel wear, brake pad thickness, and motor temperature. AI flagged issues before they became commuter nightmares, letting crews swap out parts overnight—no more morning chaos.

Smart Cities: Infrastructure That’s Actually, Well, Smart

Case Study: Metropolitan Water Utility, Middle East

- Before: Pipe bursts every 2 weeks. Water loss: 12% of supply. Repair crews always on red alert.

- After Predictive Maintenance: Pipe bursts down to 1 per quarter. Water loss cut to under 4%. Emergency callouts halved.

With a web of IoT pressure sensors and AI leak detection, the city’s water infrastructure became a model of efficiency—saving millions of liters (and dollars) annually.

What’s the Secret Sauce? Lessons Learned from the Frontlines

- Start Small: Pilot programs on critical assets build trust and deliver quick wins.

- Data is King (and Queen): The better the data, the smarter the predictions. Integrate, clean, and automate data flows.

- Train Your People: Even the best AI can’t fix a wrench dropped in the works. Upskill your teams to work with new tools.

- Iterate: Predictive models improve over time. Don’t expect perfection on day one—expect improvement every day.

"The ROI isn’t just in dollars—it’s in peace of mind. Our team sleeps better knowing the next problem is already on our radar."

— City Infrastructure Manager

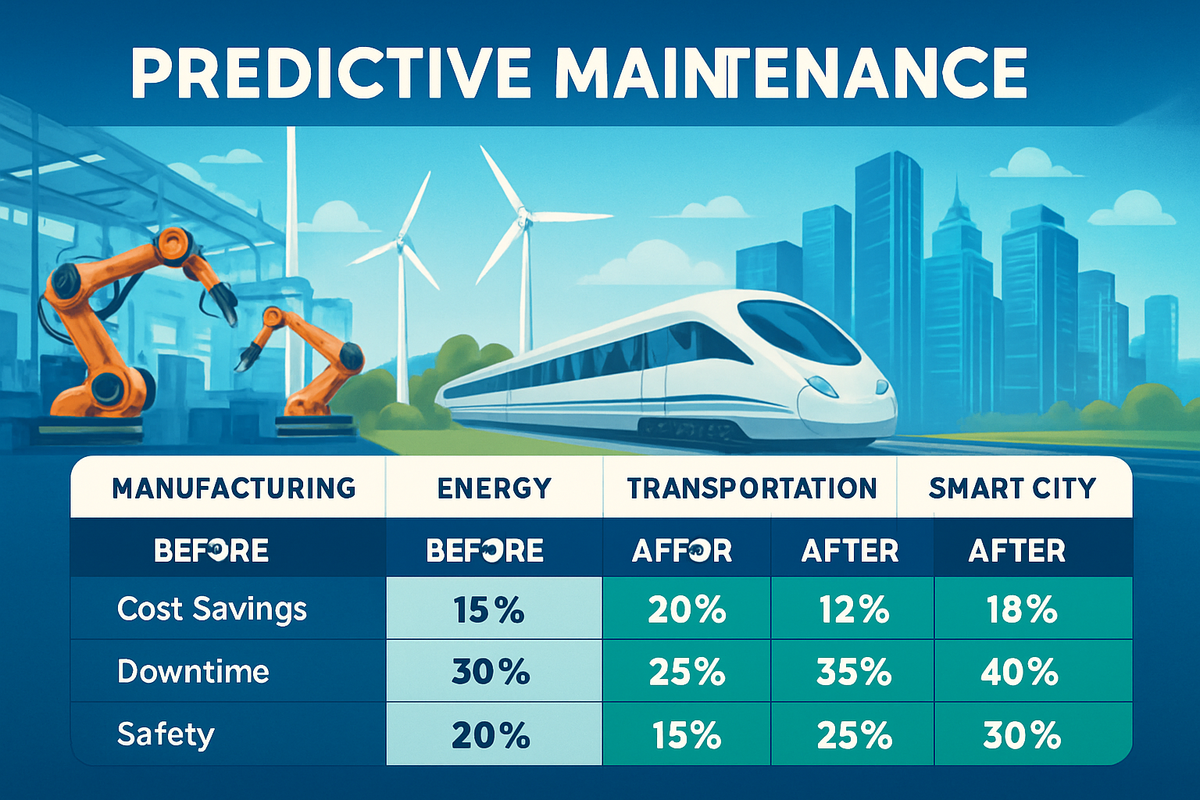

Benchmarks for Decision-Makers: What to Expect

| Sector | Downtime Reduction | Cost Savings | Safety Incidents | Sustainability Gains |

|---|---|---|---|---|

| Manufacturing | 30–50% | 12–20% | ↓ Up to 100% | Less waste, energy |

| Energy/Utilities | 40–60% | Up to 25% | ↓ 80%+ | Improved output |

| Transportation | 60–80% | Up to 30% | ↓ 60% | Fewer emissions |

| Smart Cities | 50–70% | 15–25% | ↓ 90% | Resource savings |

Ready to Join the Predictive Revolution?

If you’re a decision-maker, engineer, or city planner, the ROI on predictive maintenance is no longer a theory—it’s a competitive edge. Whether you’re chasing uptime, budget wins, or a safer tomorrow, the data and stories are clear: the future belongs to those who predict it.

Want more smart news, exclusive interviews, and actionable insights? Subscribe now to become a Funaix Insider for free—and join a community where only subscribers can read and write blog comments (yes, your hot takes are welcome). It’s free—at least for now. Don’t miss your chance to shape the conversation and stay miles ahead of the curve!

Published on July 8, 2025 • For more smart, actionable coverage, subscribe to Funaix today.