Inside the AI Factory: How Synthetic Data, Digital Twins, and Robotics Are Transforming Industry in 2025

Welcome to 2025, where AI factories transform production with synthetic data, digital twins, and adaptive robotics—creating smarter, faster, and more resilient manufacturing processes. Embrace innovation and lead the change in a rapidly evolving industry.

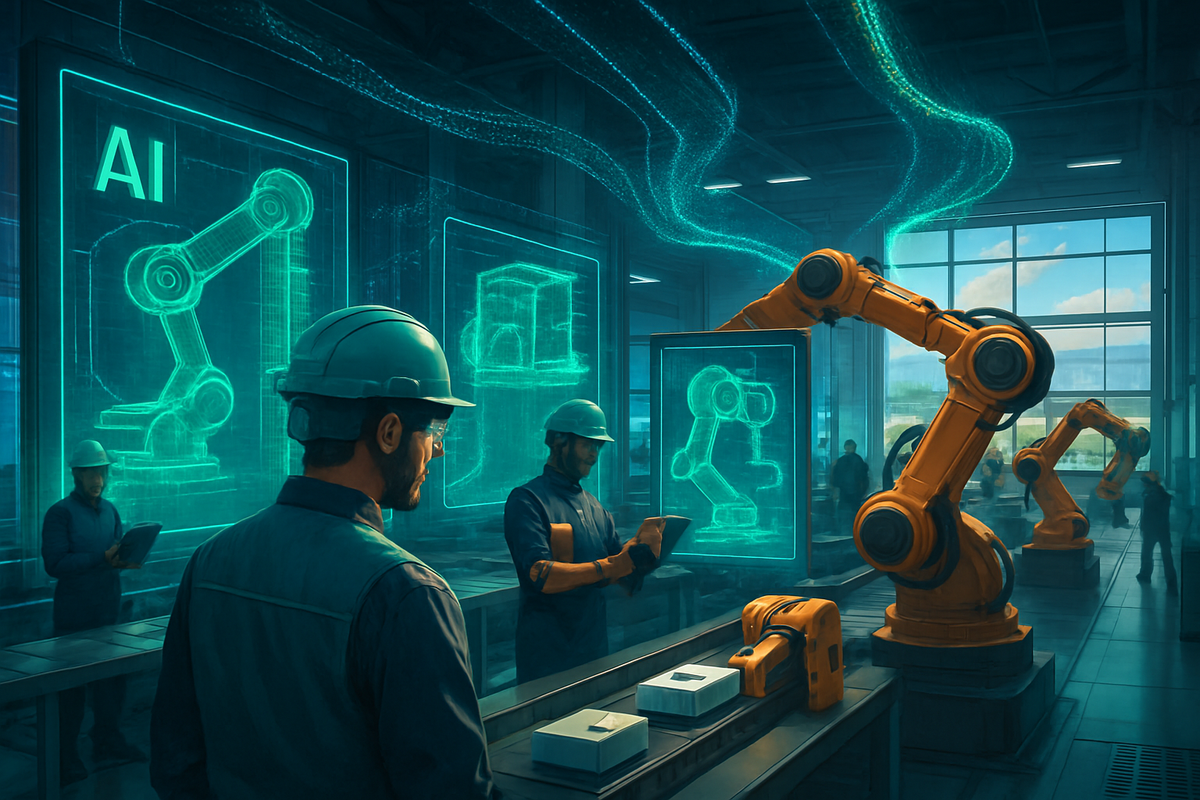

Welcome to the AI Factory: Where Science Fiction Becomes Assembly Line Reality

Imagine walking into a factory where robots don’t just assemble products—they learn, adapt, and even simulate their own mistakes before the first widget rolls off the line. Welcome to 2025, where the convergence of synthetic data, digital twins, and robotics has created the modern “AI factory”—a place where innovation hums louder than the machines.

“We’re not just making things—we’re making things smarter, faster, and more resilient. The AI factory is what happens when you give machines imagination.”

Synthetic Data: Training AI Without Breaking a Sweat (or a Widget)

In the old days, engineers had to wait for a machine to fail to learn how to fix it. Now, thanks to synthetic data—artificially generated information used to train AI models—factories can simulate thousands of breakdowns, misalignments, and cosmic-ray-induced hiccups before they ever happen. No more waiting for fate to break the conveyor belt!

- Faster AI training: Synthetic data feeds algorithms scenarios too rare (or too risky) to wait for in real life.

- Privacy by design: No need to use sensitive production data—just conjure up a safe, virtual twin.

- Continuous improvement: Models get smarter with every simulated success and failure.

According to recent industry reports, companies leveraging synthetic data for predictive maintenance have cut downtime by as much as 30%—and saved millions in the process.[1]

Digital Twins: The Mirror World of Manufacturing

Picture this: Every critical machine on your floor has a digital twin—a real-time, virtual replica that lives in the cloud (or on the edge, if you’re feeling fancy). These twins don’t just look pretty; they think. They ingest sensor data, predict wear and tear, and even run what-if simulations.

- Zero-downtime upgrades: Test new processes in the virtual world before risking the real deal.

- Root-cause analysis: When something breaks, the digital twin replays the moment in 4D slow-motion.

- Collaboration: Engineers across continents can tinker with the same virtual factory, minus the jet lag.

Fun Fact: Some manufacturers now run entire “shadow factories” in the metaverse—training AI, optimizing layouts, and debugging processes before a single screw is turned in reality.

Robotics Rebooted: From Dumb Arms to Autonomous Agents

Forget the old image of robots blindly tightening bolts. In 2025, AI-powered robots are agents: they see, decide, and adapt on the fly. With the help of synthetic data and digital twins, these bots can practice new tasks in simulation, then transfer their skills to the real world—no more costly trial and error.

- Collaborative robotics (“cobots”): Working safely alongside humans, learning from their actions.

- Autonomous inspection: Drones and mobile robots patrol facilities, spotting leaks or misalignments before you even notice a whiff of trouble.

- Self-optimizing production lines: If a bottleneck forms, the system reroutes itself, like a GPS for widgets.

Real-World Wins: How AI Factories Are Outperforming the Competition

The proof is in the productivity pudding. In the past year:

- Automotive manufacturers slashed machine downtime by 30% and cut maintenance costs by 20% with AI-driven predictive maintenance.[2]

- Energy providers boosted wind turbine uptime from 92% to 98% using digital twins and real-time analytics.

- Global electronics giants now deploy swarms of cobots, increasing output and reducing workplace injuries.

“With AI, our factory floor feels less like a grind and more like a game of strategy. If only the coffee machine could get smarter, too!”

The Road Ahead: Sustainability, Security, and the Human Touch

AI factories aren’t just about efficiency—they’re about resilience and sustainability. With smarter resource allocation, less waste, and predictive energy management, the green factory of the future is already here. But let’s not forget:

- Cybersecurity: More sensors and connections mean more digital doors for cyber-gremlins. Strong enterprise security is a must.

- Upskilling: Humans are still essential. The best AI factories invest in training their teams to work alongside (and outsmart) the machines.

Pro tip: Want to stay ahead of the curve? Subscribe to our blog at Funaix—it’s free (for now!) and only subscribers get to join the conversation in our comments. Don’t miss out on smart news, perks, and the best community of AI insiders.

Key Takeaways: Your AI Factory Checklist

- Embrace synthetic data for safer, smarter machine learning and predictive maintenance.

- Invest in digital twins to visualize, optimize, and troubleshoot your entire operation virtually.

- Deploy robotics and autonomous agents for flexible, resilient production lines.

- Prioritize cybersecurity and ongoing workforce training.

- Stay curious: The AI factory revolution is just getting started—don’t get left behind!

Sources: [1] AI-Driven Predictive Maintenance: The Future of 2025; [2] Predictive Maintenance With IoT and AI Enhances Equipment Reliability in Manufacturing. Additional insights from AP News, ITPro, and Medium.

Ready to join the AI revolution? Become a Funaix Insider and shape the future with us. Only subscribers can comment and connect. See you on the factory floor!